Engineering Services Custom Cooling System Design & Consultation Services

TAI Inc. specializes in aerospace thermal and mechanical engineering research and development services. We actively participate in the US Federal Government's SBIR/STTR program, and are on offshoot of our sister company, Technology Applications, Inc., located in Boulder, CO.

TAI Inc.'s experts have developed custom cooling and thermal control systems include:

- A refrigerated headband that has been successfully used to show enhanced performance in elite athletes

- An in-home oxygen liquefaction system capable of producing several liters of LOX per day to support the use of portable liquid units for COPD patients

- A liquid nitrogen cryostat used to cool an critical optical element in an operating laser system that greatly improves target tracking capability aboard a military platform

- Thermal acoustic barriers for thermal and noise mitigation in an advanced dual-use military vehicle

- Phase change material (PCM) heat exchangers to provide load leveling in a large antenna system used for active denial in military installations

- Remote and distributed cryogenic cooling system to mitigate vibration from mechanical cryocoolers decoupled from a gimbaled optical system for active infrared sensing

- Milli-Kelvin thermal control in a RF-tuning system utilizing Peltier devices for low temperature operation

PREVIOUS PROGRAMS AND DEVELOPMENT

CryoSpheres™ Insulation Panels (CIP)

CryoSpheres™ Insulation Panel (CIP) technology provides a low-cost, high-efficiency insulation system for the transfer and storage of cryogens and cryogenic propellants. Applications include space launch and support equipment, industrial liquefied gas production, scientific research facilities, and a broad range of high-performance thermal insulation and protection systems.

This technology was developed and patented by TAI in 2005, and was born out of research from previous Ph I and Ph II SBIR's. More information about CryoSpheres™ can be found here:

Polyethylene Flexible Cryostat Technology Development

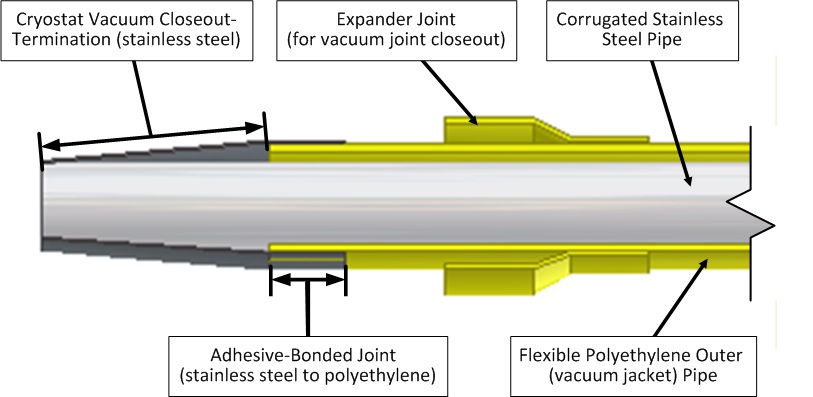

Under this previous development program, Technology Applications, Inc. (TAI) developed a new material use that has the potential to reduce the initial procurement and recurring maintenance costs and to improve on cryostat reliability issues. TAI used the already developed HTS power cable in a cryostat system developed for industrial application using known cryogenic standards, but with the new high or medium density polyethylene (H(M)DPE) materials. We used polyethylene (PE) for the outer flexible cryostat vacuum jacket rather than corrugated stainless steel for the net system benefits detailed below. The inner pipe will utilize corrugated stainless steel as currently used in HTS cryostats. The resulting hybrid design provides a reduced risk approach for incorporating low-cost PE into a HTS cable cryostat system; the design is shown in Figure 2. This hybrid cryostat approach is viable because key problems associated with vacuum integrity, degradation in service due to lightning strikes and corrosion, and life cycle cost are provided with only using PE in the outer pipe (vacuum jacket).

Figure 2. Hybrid-material cryostat for HTS cables.

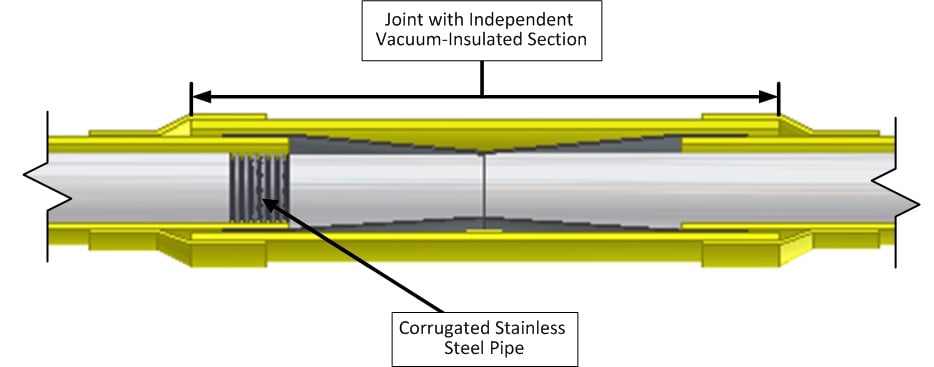

Figure 3 illustrates the design for a completed cryostat section joint that is installed in the field. This joint has an independent vacuum space with multilayer insulation as is typically used in field joints for vacuum-jacketed pipe.

Figure 3.Hybrid HTS cable cryostat joint concept.

The advanced hybrid cryostat used PE materials that are widely used commercially for underground storage tanks and piping. Given the emphasis of metal replacement by polyethylene in industrial piping as denoted by the PE100 specification implying 100-year lifetime, special polyethylenes are now available that have been toughened to survive normal environmental weathering for 100 years or more.

The use of plastics for cryogen containment is in an early stage even though plastic materials have been used in cryogenics since the 1950s. The limiting factors for more widespread use have been the development of appropriate plastics with the inherent structural capabilities of metals, manufacturability, and cost. These properties have been dramatically improved recently and have caused us to take another look at the possibility of substituting plastics for metals in cryogenic applications.

Thermoelectric Cooler Interface Development

- Thermally isolating fiberglass supports (cylindrical vacuum housing not shown).

- Assembled interface system and incorporated packaging of radar resonator.

- Uses two thermoelectric coolers (TEC) to cool to 250° K.

- Demonstrated temperature stability of less than 0.001° K.

Initially developed for infrared-sensing satellite

- All major components located in spacecraft bus

- Compressor only active component

- Flexible transfer lines route cooling fluid across busgimbaled optics

- Requires no active control with variable load

- Nearly constant temperature cooling

- Accommodates thermal load leveling

- Modular design for easy system integration

- Potential cooling applications:

- SBIRS-Low gimbal optics

- ABL course pointing sensor

- HTS resonator/waveform generator

- Vibration sensitive systems

Woven Graphite Fiber Heat Exchanger

This SBIR Ph I and Ph II contract addressed a new and innovative high-conductance graphite heat exchanger configuration. The selected TAI heat exchanger (HEX) for a Thermoelectric Generator (TEG) is based on high conductivity woven graphite heat exchanger material (GHexTM) (900 W/m-K with a mass density of 2.2 g/cm3. The HEX selected is projected to have a power density of at least 89 watts per kilogram. The very durable lightweight (217 grams) HEX is planned to be collapsed and transported in an 8x11 inch envelope or back pack. This advance in high conductivity woven graphite fibers material will create revolutionary new lightweight air heat exchanger products.

TAI was awarded US ARMY SBIR PH I and PH II awards for this work, concluding in 2020, and TAI's GHEX is available for use as a flexible heat transfer product for the aerospace industry.

Our Mission

To change the world through advancements of thermal engineering products and technologies developed by small businesses, right here in the United States.

Location

TAI Inc. is located at 5303 Spine Rd. Ste 101b, Boulder, CO 80301

Phone: 303-514-1056

Email: info@tai-inc.us and brianlsperry@yahoo.com

Our Team

Brian Sperry - CEO

Brian Sperry is owner, CEO and CTO of TAI Inc. He has been involved in thermal engineering and management since 2009 when he purchased TAI’s sister company, Technology Applications. This experience includes the analysis, engineering, and production of thermal links for Boeing’s Commercial Crew Transportation System (CCTS), Ball Aerospace’s communication system for the Orion Spacecraft, and Honeywell’s GPS IV satellites among other contracts. Mr. Sperry is currently the Principal Investigator for the design and building of a thermal convection based ThermoElectric Generator battery charger for the Army using a camp stove as a heat source. He assembled a team that commercialized graphite fiber technology for thermal conductive links. He and his team also successfully developed the copper thermal strap marketing and production capability. Previously, Mr. Sperry was a founder of Synkera Technologies. That company was sold to Integrated Technology Devices, LLC. Synkera developed and produced state-of-the-art chemical sensors based on nanotechnology and high-performance ceramics. He was a project manager with Ball Aerospace Systems working on radiation hardened video cameras and monitors, missile control systems, and imaging systems for spacecraft. Previously, he worked for Beech Aircraft Corp producing cryogenic systems for the space shuttle. Before that, at General Electric Company, he was an inertial guidance system engineer.

He has a B.S. Electrical Engineering from the University of Colorado (1967), an MBA Finance also from the University of Colorado (1973), and is a Certified Professional Contract Manager (1987).

Copyright © 2021 TAI Inc. - All Rights Reserved.

303-514-1056 brianlsperry@yahoo.com

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.